Safety Switch

The Twin Falls gate pivots straight up in a most grand manner

Unfortunately it has no safety switches

History of the Gate

This "Sun Power" gate was

purchased and installed in 1993 by the new owners of the 180 acres

surrounding King Lake.

The gate fell into disrepair after a few years. It quit working and was

left open for several more years.

In 1999 vandals started a forest fire at the end of the road and

the owners had to fix the gate to limit people on the roads.

Some residents living up the road got together and hired a local

electronics tech to

take over the maintenance, upkeep and maintain the keypad access list.

The "free exit" loop eventually failed and was replaced with an

aftermarket loop sensor.

The new loop sensor was connected and a

puzzling situation developed.

The Problem

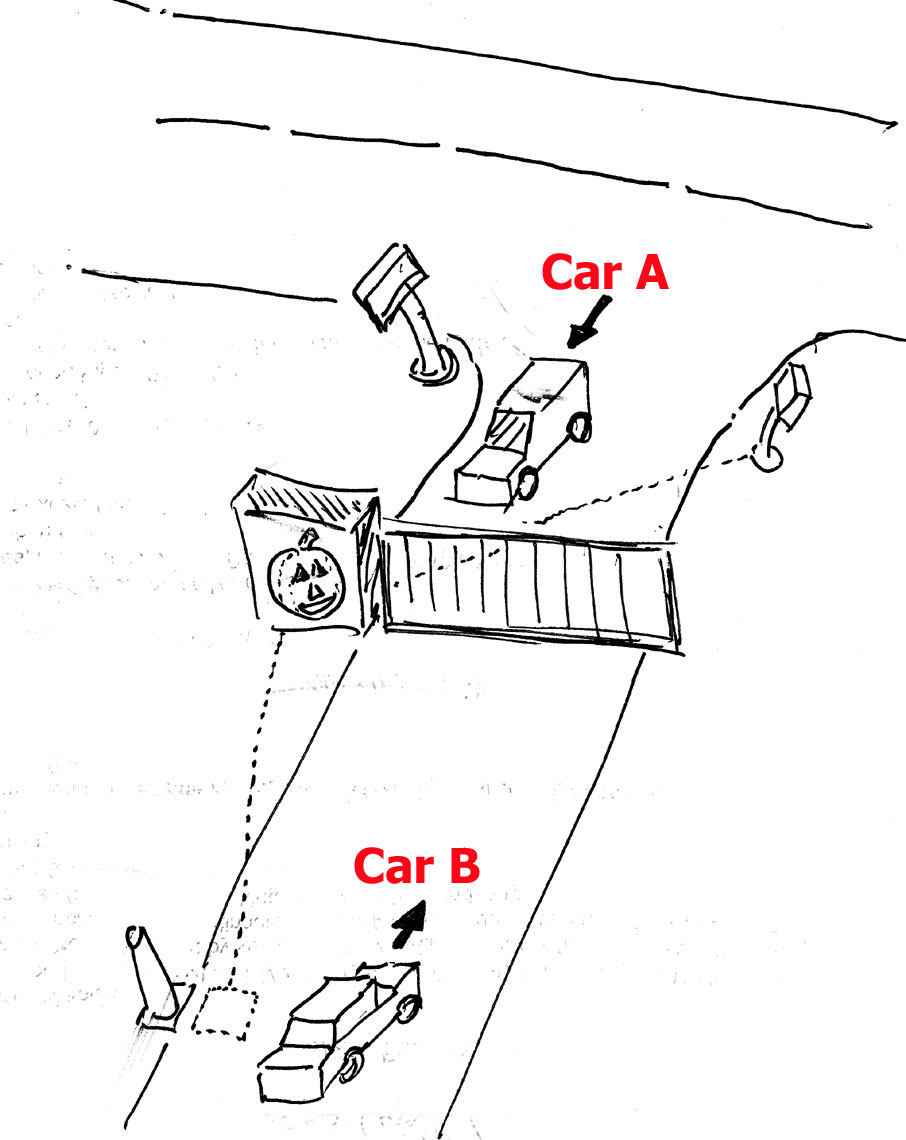

If the gate was open for car A to enter, and Car B drove past the free

exit sensor, the gate would abruptly and rapidly close without warning.

This situation happened more times

than you would think.

The gate would also close quickly if one car tried to 'tailgate' another

car through the gate and wasn't fast enough.

The first car would trigger an immediate close on top of the second car.

Similarly, large trucks could trigger the close sensor before they were

completely through the gate.

The community put out a letter that warned people to watch for

situations where two cars met at the gate and triggered the exit loop.

The gate never had any schematics for the logic box and commercial gate

companies just scratched their heads.

There was no way to figure out the

gate logic so we came up with an idea to disable the exit loop sensor when

the gate was open. This would allow any cars to arrive and depart as

long as the 2 minute "open" timer was counting down.

This scheme involved repurposing a sensor used to count objects off of a conveyor belt. We'd

use it to "optically" sense the gate position and open the circuit to the

exit loop as long

as the gate was open

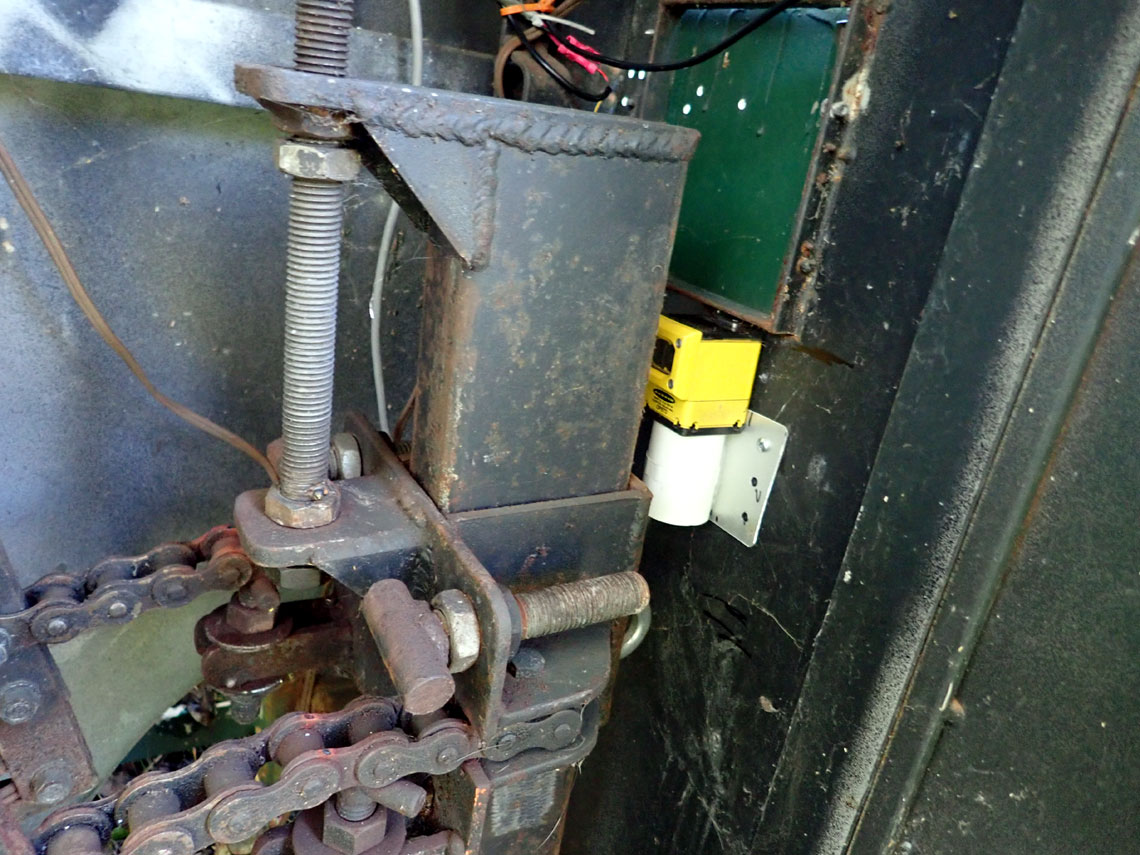

Here's the opening mechanism or "operator"

The seven big springs in the box effectively counterbalance the weight

of the gate so that a small battery-powered motor can open and close the

gate.

This big "foot" is connected to the gate and is pulled on by the

springs.

Yellow thing is the conveyor belt sensor we used to sense the gate

position.

Its called an OPBT2 by Banner Industries

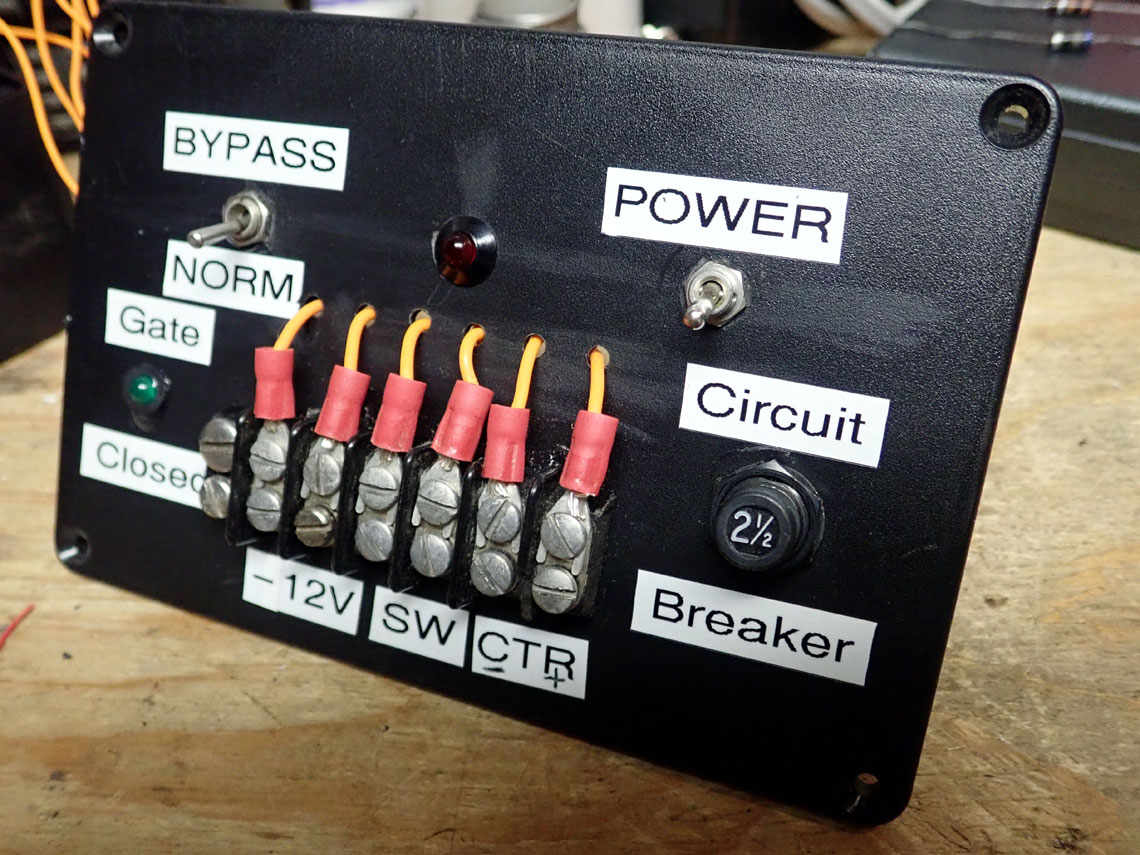

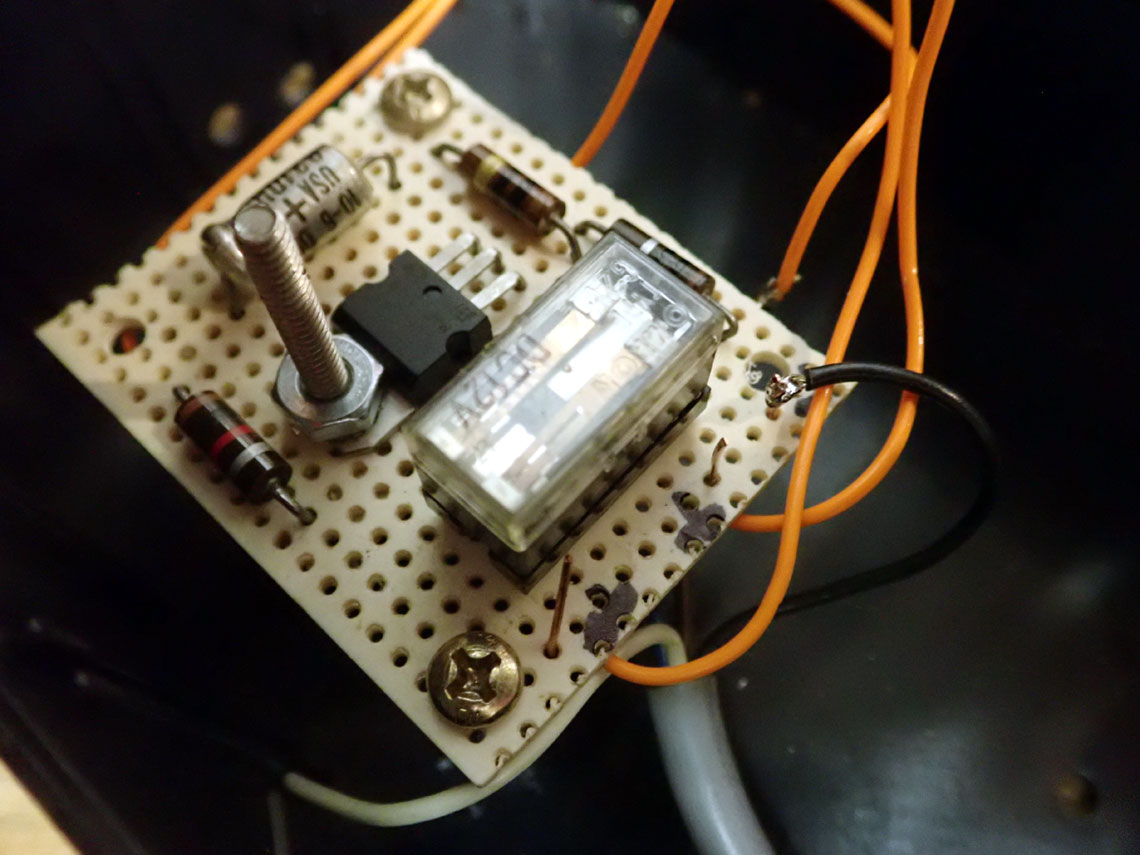

Final Testing on the bench

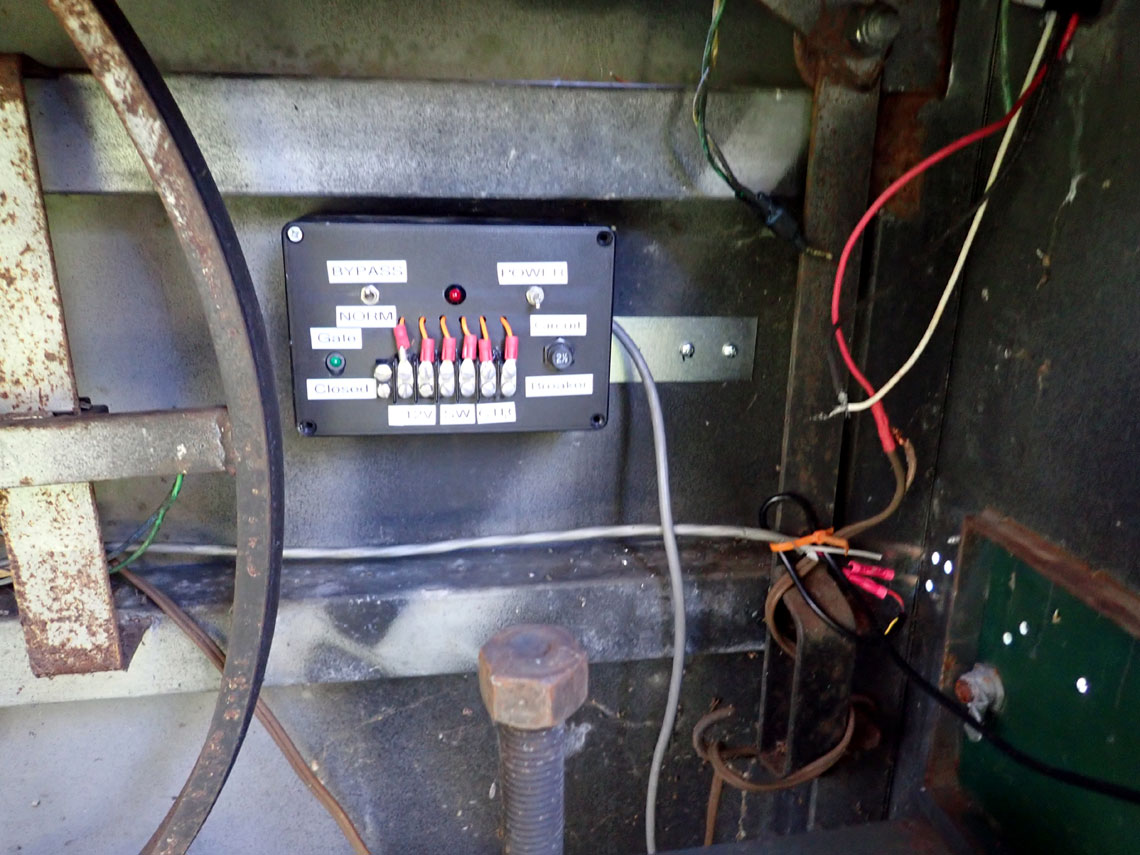

Control Box mounting

The new control box

Design Criteria

The device should not be physically wired to the gate logic except

to interrupt the incoming signal from the exit detector.

The device had to be simple, foolproof and easy to install.

The parts count should be the minimum necessary.

The device could never cause the gate

to close.

The device has to be wired into the gate box a non invasive way.

The device has to run on 12 volt power.

The device should have a "bypass" switch in case of a failure of the

parts in the control box

The device should have sufficient

indicator lights so anyone looking at the front panel will know what it

is doing.

The device should have a fuse or circuit breaker.

The device should incorporate a counter so the maintainers have an idea

of how many the times the gate has opened and closed.

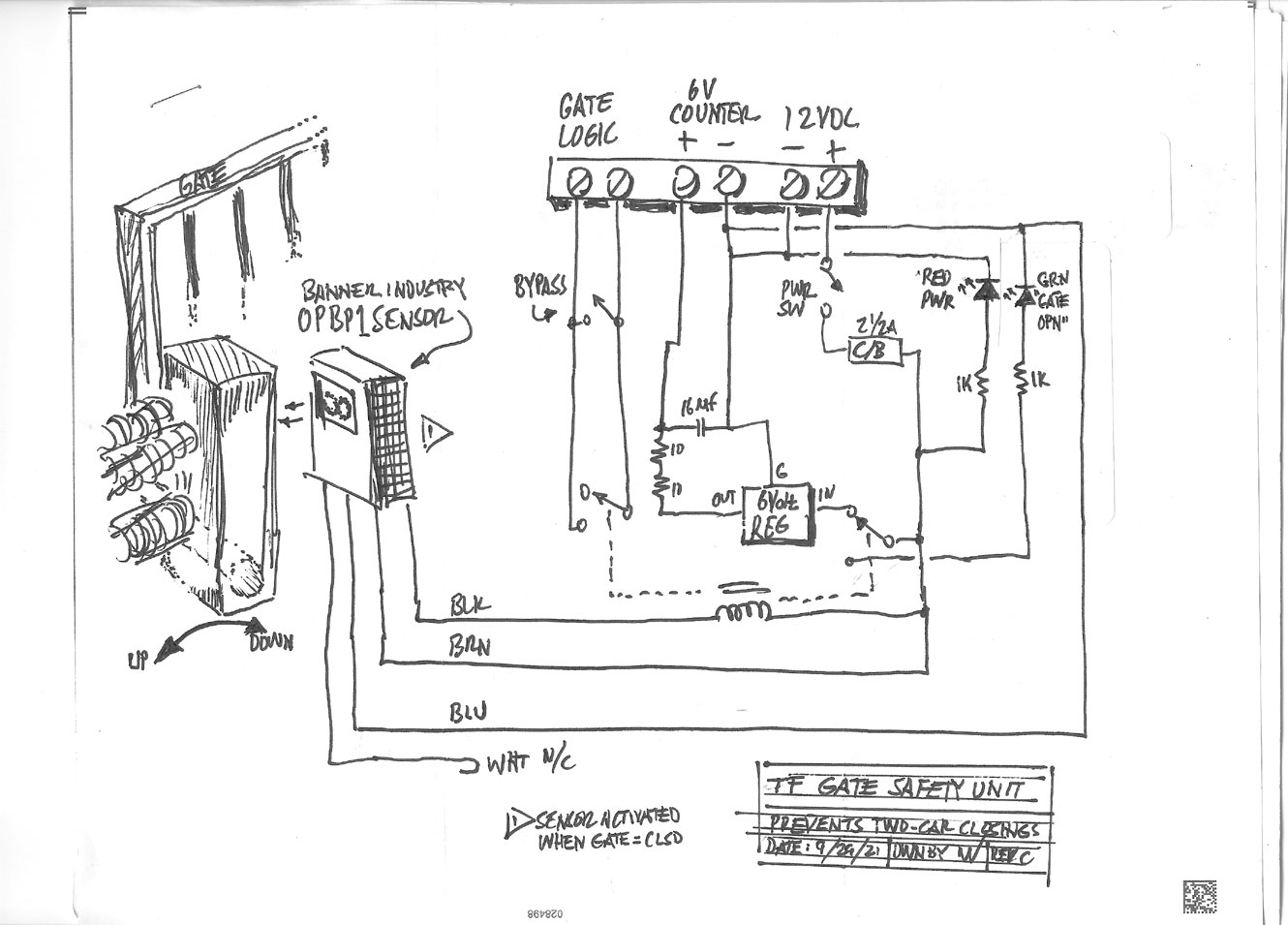

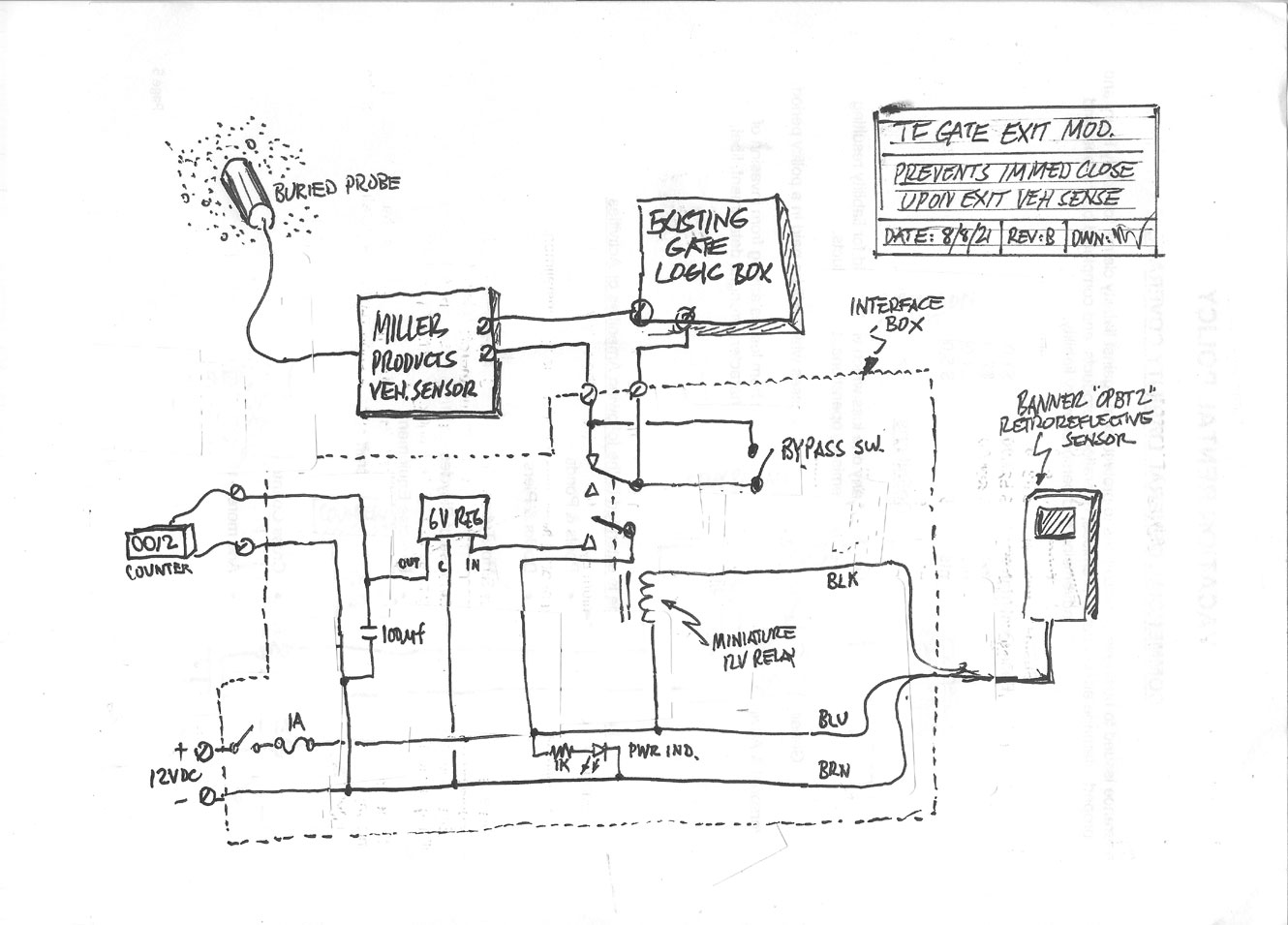

Logic circuit

Schematic diagram

An early drawing of the proposed system

Fire truck and crew in 2019

Trying to figure

out how the gate operates and how to open it!

10/21/21