Power wiring addition Summer 2021

This was a long overdue project

Power and telephone run underground across the gravel

road to the new machine barn. Grey line is existing 220V feed to a sub

panel. Black line is the new addition.

Kubota tractor seen pulled inside

Approximate location of underground 120 Volt power

and telephone cable run.

Yellow machine is the treefarm

Komatsu dozer with six-way blade.Camo machine is the eight ton class

Komatsu mini excavator. Blue

can is catching an "insignificant" oil drip.

All we needed was a floodlight pair and an outlet in

this building

PVC conduit made the whole thing a bit weatherproof even though it is

undercover. We wanted this end of the 120V power to be uncluttered and

clean.

Small workstation with adjacent switch and outlet

Magneto phone not yet mounted on panel to the far left.

Note oil filter box tops stapled to wall as we can never remember which

three filter part #'s for which of the three diesel machines!

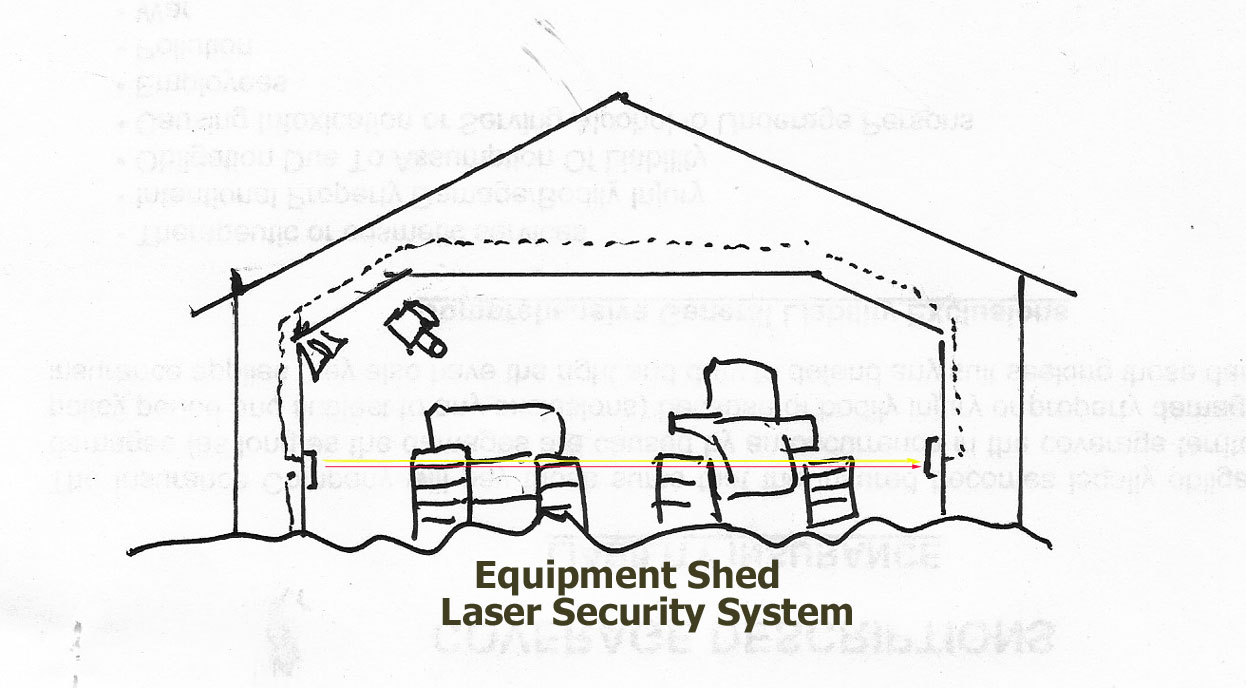

We decided to add a laser beam "tripwire" security system as the tractor

shed is open and vulnerable to pilferage. Found

this

one at our favorite surplus store. It tested good on the bench and

the idea of a tiny red laser seemed fun.

Here's the laser transmitter installed and aligned to

the receiver 18' across the opening

Note the 3/4" indent of the wood block for a later plywood concealment

cover.

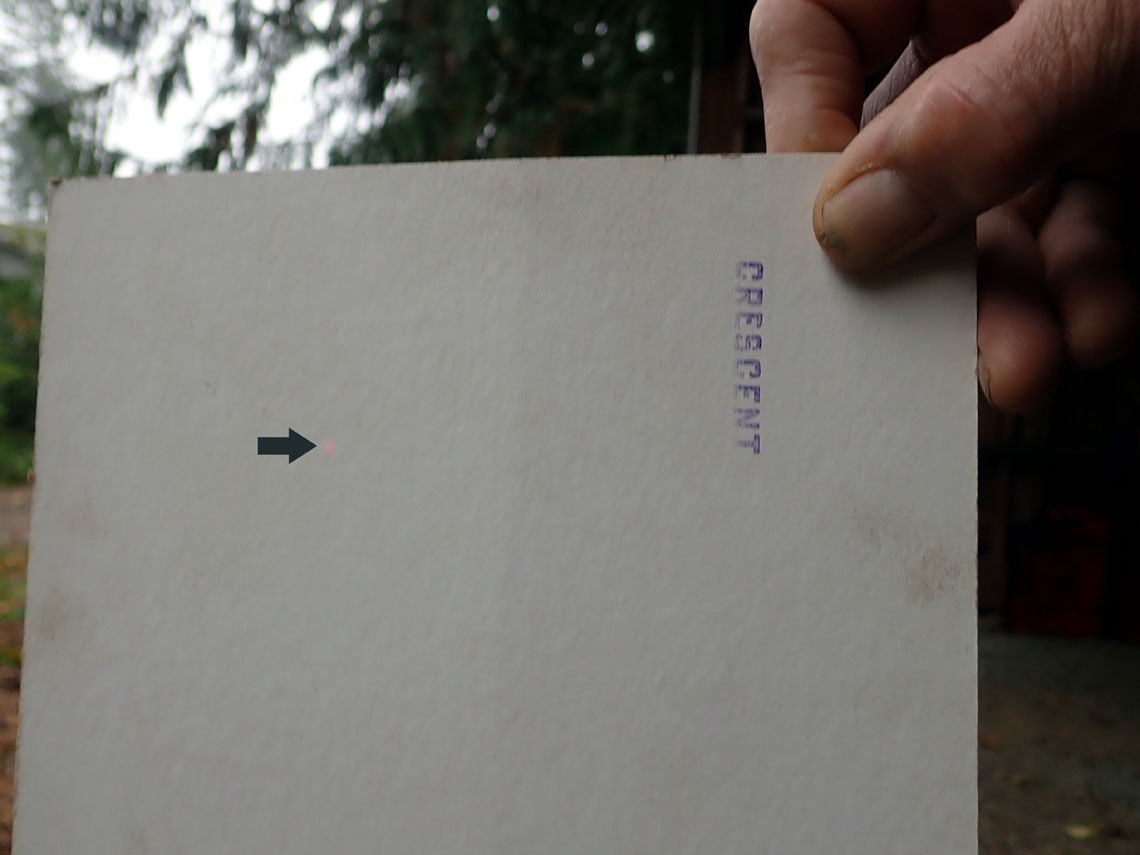

A Google search reveals

many ideas out there

Initial installation

The laser receiver (bottom of photo) during initial testing and

alignment.

Black wire above is the 4 pair direct bury telephone wire from the other

building.

Grey wire dropping from above is the power wire to the laser transmitter

over the top 18' across the opening. Other grey wire is for the magneto

telephone, hidden on-off switch and power on LED next to the

workstation.

A disappointment

After three days the laser dot became dimmer and dimmer.

We got our $20 back but here's what we envisioned

Option B

Utilize a surplus commercial IR photoelectric driveway minder found in

the bottom of our electronics junk box. This unit was up, aligned and

running in a few minutes. It uses a reflector on the opposite wall. It

also came with more complications: It required 24VAC and we also needed

12VDC for the alarm driver.

Close-up of the commercial photo beam unit.

Note the barrier strip wired for power, signaling and magneto phone

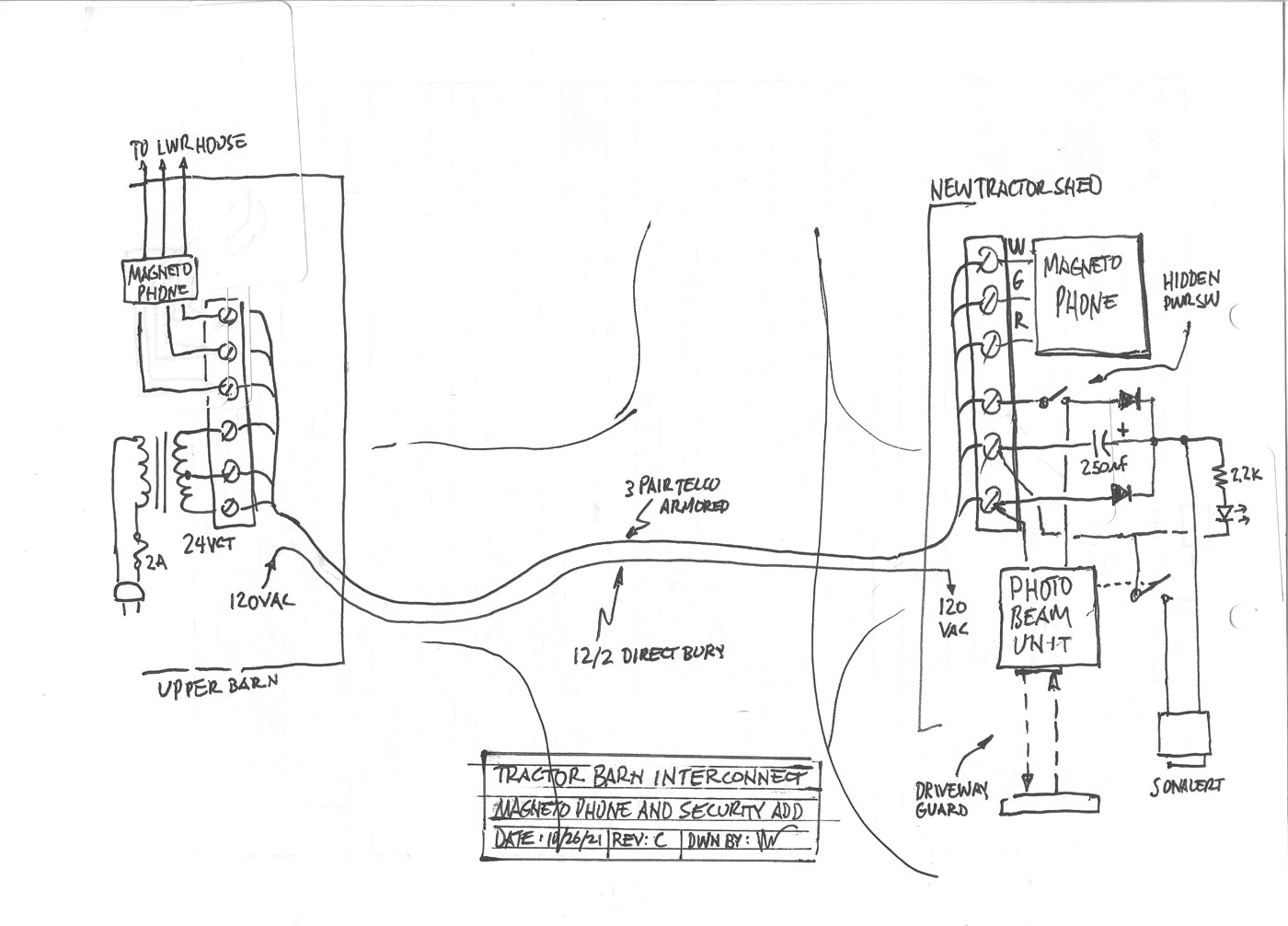

Schematic diagram of the setup

How it works:

The 24VAC center-tapped transformer in the older garage sends 12 and 24

volts AC through the phone cable to the terminal strip in new garage.

The commercial photo beam unit needs 24 volts AC and the remote center

tapped transformer provides a novel "two diode" DC power supply

configuration. We now have 12 volts DC for the alarm. A filter capacitor

to smooth the rectified DC and a hidden on-off switch and LED round out

the design. With six 22ga telephone wires, we utilize three wires

for the magneto phone and have three wires for the remote power. This

eliminates a messy 120VAC connection and 120 Volt wiring in the new equipment

shed. New shed AC power design requirement: Only a sterile

install, a light switch, floodlight pair and outlet.

Commercial photo unit with simulated beam

Note the line where its wet and dry from recent NW rains

Completed unit with plywood concealment cover

Note the brown painted junction box bottom center where the wires come

up from the underground run.

11/16/21